585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

Top 10 Benefits of Using Corrugated Trays for Your Packaging Needs

When it comes to packaging solutions, businesses continually seek materials that combine efficiency, sustainability, and cost-effectiveness. Among the various options available in today’s market, corrugated trays have emerged as a popular choice for many industries. These versatile trays are not only lightweight but also provide excellent durability, making them an ideal packaging solution for a wide range of products. Their unique structure offers enhanced protection, ensuring that goods remain intact during transportation and storage.

Moreover, the benefits of using corrugated trays extend far beyond mere physical protection. They are designed to be environmentally friendly, as they are made from recyclable materials and can significantly reduce waste. Additionally, corrugated trays can be customized in terms of size, shape, and design, allowing businesses to create a packaging solution that meets their specific needs. This adaptability, combined with their cost-effectiveness, positions corrugated trays as an optimal choice for companies aiming to streamline their packaging processes while maintaining a commitment to sustainability. In this article, we will explore the top 10 benefits of using corrugated trays for your packaging needs, highlighting why they are increasingly favored in the marketplace.

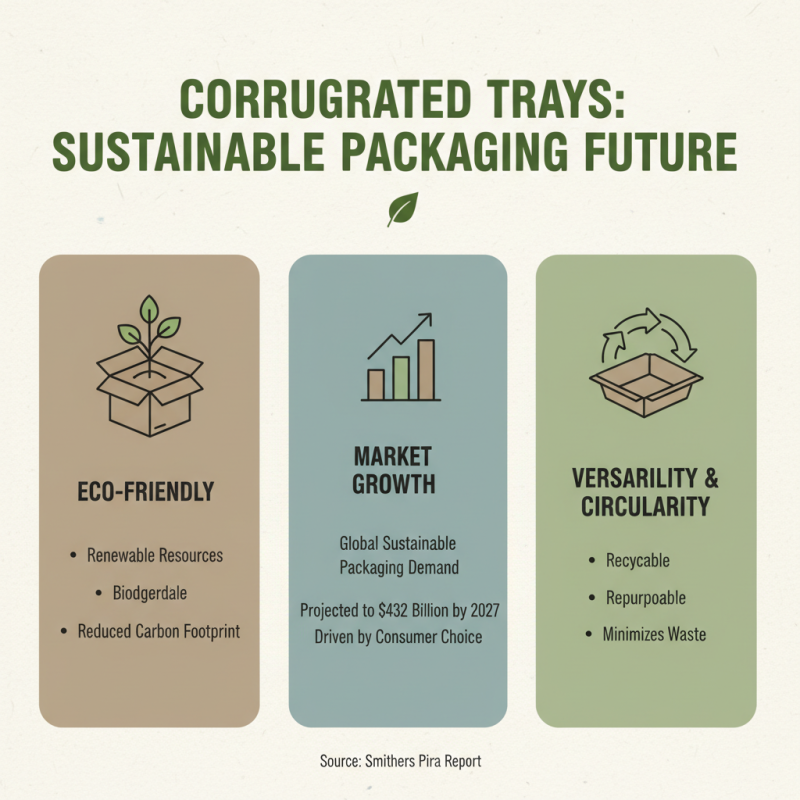

Benefits of Corrugated Trays in Sustainable Packaging Solutions

Corrugated trays are emerging as a crucial component in sustainable packaging solutions, primarily due to their eco-friendly characteristics and versatility. According to a recent report from Smithers Pira, the global demand for sustainable packaging is projected to grow to $432 billion by 2027, driven largely by consumer preference for environmentally responsible products. Corrugated trays, made from renewable resources, contribute significantly to this trend by offering a biodegradable alternative to traditional plastic options. Their ability to be recycled and repurposed not only minimizes waste but also reduces the carbon footprint associated with packaging processes.

In addition to their environmental benefits, corrugated trays provide a practical solution for various industries. They are lightweight yet sturdy, offering excellent support for goods during transit while reducing shipping costs. The flexibility in design allows for customization to fit specific product dimensions, further enhancing their efficiency in protecting items. The Fibre Box Association highlights that over 90% of corrugated products in the U.S. are recycled, showcasing a well-established recycling infrastructure that supports a circular economy. By opting for corrugated trays, businesses can align with sustainability goals, elevate their brand reputation, and cater to the growing environmentally-conscious consumer base.

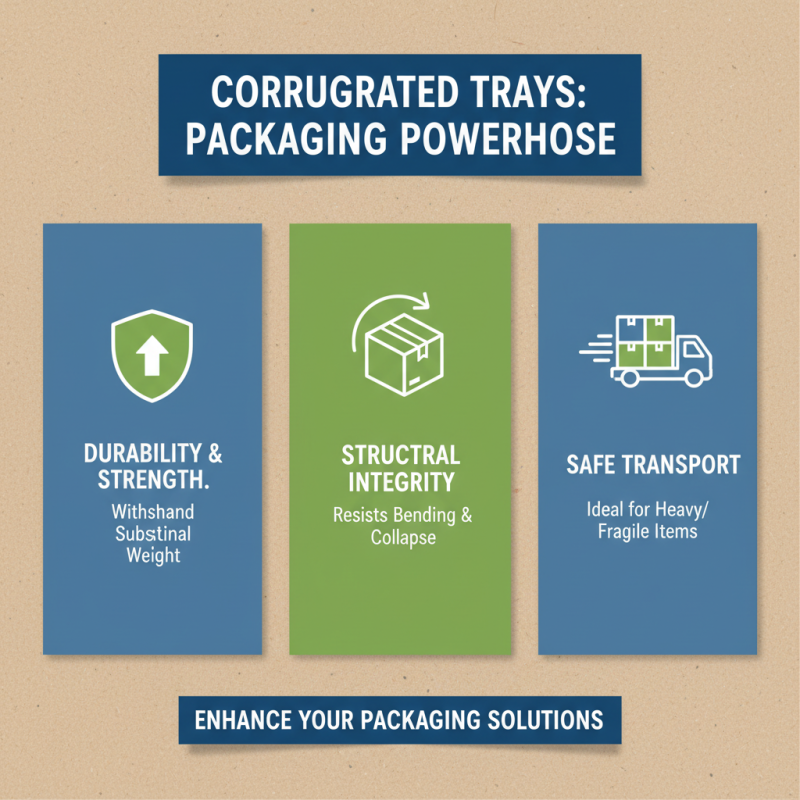

Durability and Strength: Key Advantages of Corrugated Trays

Corrugated trays have become a popular choice for businesses looking to enhance their packaging solutions, primarily due to their remarkable durability and strength. Made from layers of cardboard, these trays provide excellent structural integrity, allowing them to withstand substantial weight without compromising their shape. This characteristic is essential for industries that need to transport heavy or fragile items, as the trays can safely support these products during shipping and handling. The resistance to bending and collapsing ensures that goods remain intact throughout the distribution process.

When selecting corrugated trays, it's crucial to consider their stacking capabilities. Properly designed trays can be easily stacked, which maximizes storage efficiency and minimizes warehouse space usage. Additionally, using corrugated trays can reduce the risk of damage to fragile goods, as they can absorb shocks and impacts better than traditional packaging materials.

Tips for using corrugated trays effectively include ensuring that they are correctly sized for your products to avoid overloading, which can lead to breakage. Also, consider reinforcing the trays with additional corner supports when shipping heavier items to enhance stability. Lastly, always opt for eco-friendly options, as many corrugated trays are recyclable, aligning your packaging strategies with sustainability goals.

Cost-Effectiveness of Using Corrugated Trays for Businesses

Corrugated trays have gained significant popularity in packaging solutions due to their remarkable cost-effectiveness for businesses. One of the primary advantages of using corrugated trays lies in their lightweight design, which not only reduces shipping costs but also lowers the overall carbon footprint of transportation. By minimizing the weight of packaging materials, companies can optimize their logistics and save on freight expenses, making corrugated trays an economical choice for managing supply chain costs.

Moreover, the production of corrugated trays can be tailored to meet specific business needs, allowing companies to scale their packaging solutions without incurring exorbitant costs. Custom sizes and designs enable businesses to maximize space efficiency, which reduces the volume of materials required and further diminishes production costs. Additionally, these trays are recyclable and often made from recycled materials, providing companies with an eco-friendly option that aligns with sustainability goals. This not only appeals to environmentally conscious consumers but can also result in tax benefits and enhanced brand reputation, ultimately contributing to long-term savings.

Top 10 Benefits of Using Corrugated Trays for Your Packaging Needs

| Benefit | Description | Cost Savings (%) | Sustainability Impact |

|---|---|---|---|

| Lightweight | Easier handling and transportation. | 20% | Reduces fuel consumption. |

| Customizable | Easily tailored to product dimensions. | 15% | Minimizes waste. |

| Stackability | Designed for efficient space utilization. | 10% | Optimizes storage space. |

| Durability | Resistant to moisture and impact. | 25% | Longer product life. |

| Eco-Friendly | Made from recyclable materials. | 18% | Promotes sustainability. |

| Protection | Provides cushioning for fragile items. | 30% | Reduces damage during transit. |

| Cost-Effective | Lower production and shipping costs. | 22% | Maximizes budget efficiency. |

| Versatility | Suitable for various industries. | 16% | Adaptable packaging solution. |

| Branding Opportunities | Allows for custom printing and designs. | 12% | Enhances brand visibility. |

| Easy Disposal | Simple to recycle or dispose of. | 14% | Minimizes landfill waste. |

Versatility of Corrugated Trays for Various Product Types

Corrugated trays have emerged as a versatile packaging solution, capable of accommodating a wide variety of product types across different industries. Their structural design offers the right balance of strength and lightweight convenience, making them suitable for fragile items like ceramics, food products, and electronics. Manufacturers and retailers appreciate the adaptability of corrugated trays, which can be custom-made to meet specific dimensions and weight requirements, ensuring that products remain secure during transportation and storage.

Additionally, the eco-friendly nature of corrugated material enhances its appeal for businesses looking to adopt sustainable practices. Corrugated trays can be easily recycled, reducing the overall environmental impact of packaging. This versatility extends beyond just product protection; they can also be utilized for promotional displays, making them an excellent choice for marketing campaigns. With their ability to efficiently package various goods while also enhancing visual presentation, corrugated trays are an indispensable resource for manufacturers focused on both functionality and sustainability in their packaging choices.

Enhanced Protection and Safety Features of Corrugated Trays

Corrugated trays have become a preferred choice for packaging due to their enhanced protection and safety features. These trays are designed to provide superior cushioning against impacts, ensuring that products remain undamaged during transportation and storage. The structural integrity of corrugated materials allows them to withstand heavy weights while maintaining their shape, minimizing the risk of product breakage. Additionally, their lightweight nature reduces shipping costs, making them an economical option for businesses looking to optimize their packaging processes.

Tips for maximizing the protective benefits of corrugated trays include choosing the right thickness based on the weight and fragility of your items. Thicker corrugated materials can better absorb shocks and prevent crushing, while fluted designs increase rigidity. Furthermore, consider using dividers or inserts made from corrugated board to keep items separated and secure within the tray, further enhancing safety.

Another important aspect is to ensure that the trays are sealed properly. Using appropriate sealing techniques, such as reinforcing the edges and corners with tape or strapping, can prevent accidental openings that could lead to product damage. Ultimately, utilizing corrugated trays not only safeguards your products but also contributes to a more sustainable packaging solution due to their recyclable nature.

Related Posts

-

10 Best Corrugated Trays You Should Consider for Your Business

-

2025 How to Choose the Best Plastic Storage Containers for Every Need

-

Exploring the Future of Packaging: How Thermoforming is Revolutionizing Sustainable Solutions

-

Exploring the Innovations in Best Plastic Bins with Lids for 2025

-

7 Amazing Benefits of Using the Best Spill Tray for Your Business

-

The Future of Best Vacuum Forming Technologies in 2025 Your Ultimate Guide to Innovations