585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

How to Choose the Best Industrial Storage Bins for Your Business Needs

In the fast-paced world of modern industries, efficient organization and optimal space utilization are paramount for operational success. Industrial storage bins play a critical role in achieving these goals, as they provide an effective means of sorting and storing materials, tools, and components. According to a recent report by the Material Handling Industry of America, the effective implementation of storage solutions can lead to a significant increase in productivity—reportedly by up to 25%—by minimizing the time workers spend searching for items.

Choosing the right industrial storage bins is essential for streamlining inventory management and ensuring a smooth workflow. With a wide variety of materials, sizes, and designs available on the market, businesses must carefully evaluate their storage needs and the specific requirements of their operational environment. A study published by the Warehousing Education and Research Council highlights that well-organized storage systems can reduce operational costs by as much as 30%, emphasizing the importance of this decision for businesses striving to remain competitive.

As we delve into the process of selecting the best industrial storage bins for your unique business needs, it is crucial to consider factors such as load capacity, durability, material, and ergonomic design. By making informed choices, companies can enhance their efficiency, safety, and overall productivity in a rapidly evolving industrial landscape.

Understanding Different Types of Industrial Storage Bins Available

When selecting industrial storage bins, it's crucial to understand the various types available, as each serves distinct purposes and environments. Commonly, bins can be classified into plastic, metal, and wood types. Plastic bins are lightweight and resistant to moisture, making them ideal for applications in food processing and pharmaceuticals. Their durability and ease of cleaning make them a popular choice for businesses that require hygiene standards. Additionally, many plastic bins come in stackable designs, allowing for efficient space utilization in warehouses.

On the other hand, metal storage bins are favored in industries that require heavy-duty options, such as manufacturing and automotive. These bins offer superior strength and are often used for storing heavy components or tools. They can withstand harsh environments and are designed to endure significant wear and tear. While they may be heavier and not as versatile in terms of mobility, their robust nature provides unparalleled protection for valuable items.

Finally, wooden storage bins are a classic choice and are often utilized in agriculture and retail settings. Known for their aesthetic appeal and eco-friendliness, wooden bins are suitable for bulk storage and can be customized for various uses. They tend to be less suitable for environments with extreme moisture or temperature fluctuations but offer a rustic charm that can enhance product display or storage. Understanding these various types helps businesses determine which industrial storage bin aligns best with their operational requirements.

Comparison of Different Types of Industrial Storage Bins

Assessing Your Business Needs for Storage Solutions

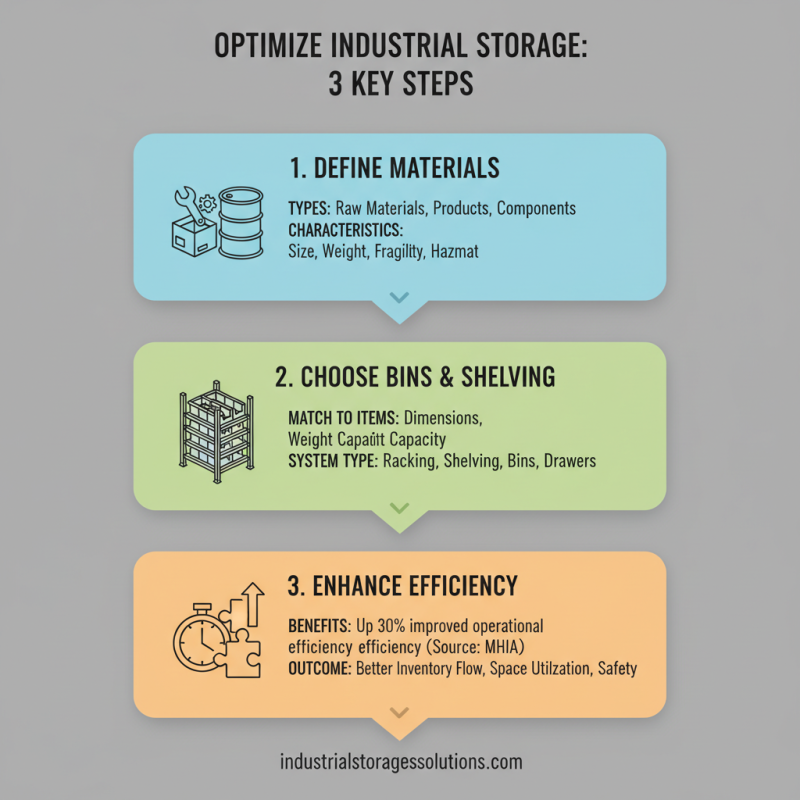

When assessing your business needs for industrial storage solutions, the first step is to clearly define the types of materials and products you will be storing. According to the Material Handling Industry of America (MHIA), an effective storage system can increase operational efficiency by up to 30%. This highlights the importance of choosing bins designed to accommodate both the size and weight of items, which in turn can dramatically affect inventory flow and space utilization. An understanding of the dimensions and weights of items can aid businesses in selecting storage bins that maximize space while ensuring safety and ease of access.

Additionally, consider the specific environment in which the storage bins will be utilized. Different industries have unique requirements; for instance, food manufacturing may necessitate bins that are easy to clean and made of non-toxic materials, while warehouses for automotive parts might prioritize durability and resistance to harsh chemicals. Research from the Warehousing Education and Research Council (WERC) indicates that a tailored approach to material handling can reduce storage costs by 15% while improving operational efficiency. By aligning your storage bin choices with your specific business operations and needs, you can create a more organized and efficient work environment that supports growth and productivity.

Factors to Consider When Choosing Storage Bin Materials

When selecting industrial storage bins, the material from which they are made plays a crucial role in determining their effectiveness and longevity.

There are several common materials to consider, such as plastic, metal, and wood.

Each material has its own strengths and weaknesses that can impact your operations. According to a report by the Material Handling Industry, approximately 70% of company decision-makers noted that the choice of storage bin materials directly influenced their supply chain efficiency.

Plastic storage bins, for example, are lightweight, resistant to corrosion, and easy to clean, making them ideal for industries that handle chemicals or food products.

Recent studies reveal that plastic bins can reduce the risk of contamination by up to 40%, which is vital for maintaining safety and compliance standards.

On the other hand, metal storage bins offer superior strength and durability, suitable for heavy-duty applications.

They withstand high temperatures and are resistant to impact, but can be prone to rust if not properly treated.

Wooden bins, while offering a traditional and sturdy option, may not be suitable for all environments due to wood's propensity to absorb moisture and harbor pests.

However, they can be an excellent choice for storage in dry conditions or when aesthetic appeal is a factor, as 60% of businesses reported a preference for natural materials in creative spaces.

Ultimately, the choice of material should align with the specific challenges and requirements of your industry, ensuring functional efficiency and long-term value.

Evaluating Size and Capacity Requirements for Efficiency

When selecting industrial storage bins, evaluating size and capacity requirements is crucial for operational efficiency. First, consider the specific items you need to store. Different products have varying shapes and dimensions. By accurately measuring the largest items, businesses can determine the appropriate bin size that accommodates these products while allowing for proper organization. Furthermore, analyzing the storage area’s dimensions is essential to ensure that bins can be utilized without obstructing movement or workflow.

In addition to dimensions, capacity requirements play a significant role in choosing the right storage bins. It's important to evaluate the volume of inventory expected at any given time and select bins that can handle this load without risk of overflow or damage. For example, businesses experiencing seasonal fluctuations in stock should consider bins with flexible capacity. Additionally, implementing bins with modular designs allows for easy expansion as business needs grow, ensuring that the storage solution remains effective and efficient over time. Making informed decisions based on size and capacity helps optimize storage space and enhances overall productivity.

Budgeting for Industrial Storage Bin Investments and Cost Management

When budgeting for industrial storage bin investments, it is crucial to consider both upfront costs and long-term savings. Start by evaluating the specific storage needs of your business, which can significantly influence the types of bins you require. Investing in high-quality bins may have a higher initial cost, but they often offer greater durability and efficiency in the long run. Consider the materials and construction of the bins, as these factors will directly impact their lifespan and performance. Additionally, factor in any maintenance costs associated with different bin types—some may require more upkeep than others.

Cost management is essential to maximize return on investment. Once you have a clear understanding of your needs and potential costs, it's prudent to explore bulk purchasing options or supplier discounts, which can lead to substantial savings. Regularly assessing the efficiency of your storage solutions can also help identify areas for cost reduction. Implementing a system for tracking inventory levels and bin utilization can ensure that your spending aligns with actual usage, helping to avoid over-purchasing or wasted resources. By strategically planning your budget and continuously monitoring costs, your business can achieve streamlined operations without unnecessary financial strain.

How to Choose the Best Industrial Storage Bins for Your Business Needs

| Type of Storage Bin | Material | Capacity (Liters) | Cost per Unit ($) | Ideal Use Case |

|---|---|---|---|---|

| Plastic Storage Bin | Polypropylene | 50 | 15.00 | Warehouse storage |

| Metal Container | Steel | 100 | 45.00 | Heavy-duty applications |

| Stackable Bin | Polyethylene | 30 | 10.00 | Small parts storage |

| Conductive Bin | Conductive Plastic | 40 | 25.00 | Electronic components |

| Heavy-Duty Tote | Polypropylene | 70 | 38.00 | Manufacturing parts |

Related Posts

-

How to Choose the Right Industrial Storage Bins for Your Business Needs

-

7 Best Ways Plastic Stackable Bins Can Transform Your Storage Solutions

-

Innovative Trends in Industrial Storage Bins Showcased at the 138th China Import and Export Fair 2025

-

Maximize Space: The Ultimate Guide to Heavy Duty Plastic Storage Boxes for All Your Storage Needs

-

Exploring the Future of Packaging: How Thermoforming is Revolutionizing Sustainable Solutions

-

Understanding the Advantages of Vacuum Forming Machines in Modern Manufacturing Processes