585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

Exploring the Future of Packaging: How Thermoforming is Revolutionizing Sustainable Solutions

The packaging industry is undergoing a significant transformation as sustainability becomes a top priority for manufacturers and consumers alike. Recent reports indicate that the global sustainable packaging market is projected to reach $500 billion by 2027, with a compound annual growth rate (CAGR) of 7.7% from 2020 to 2027.

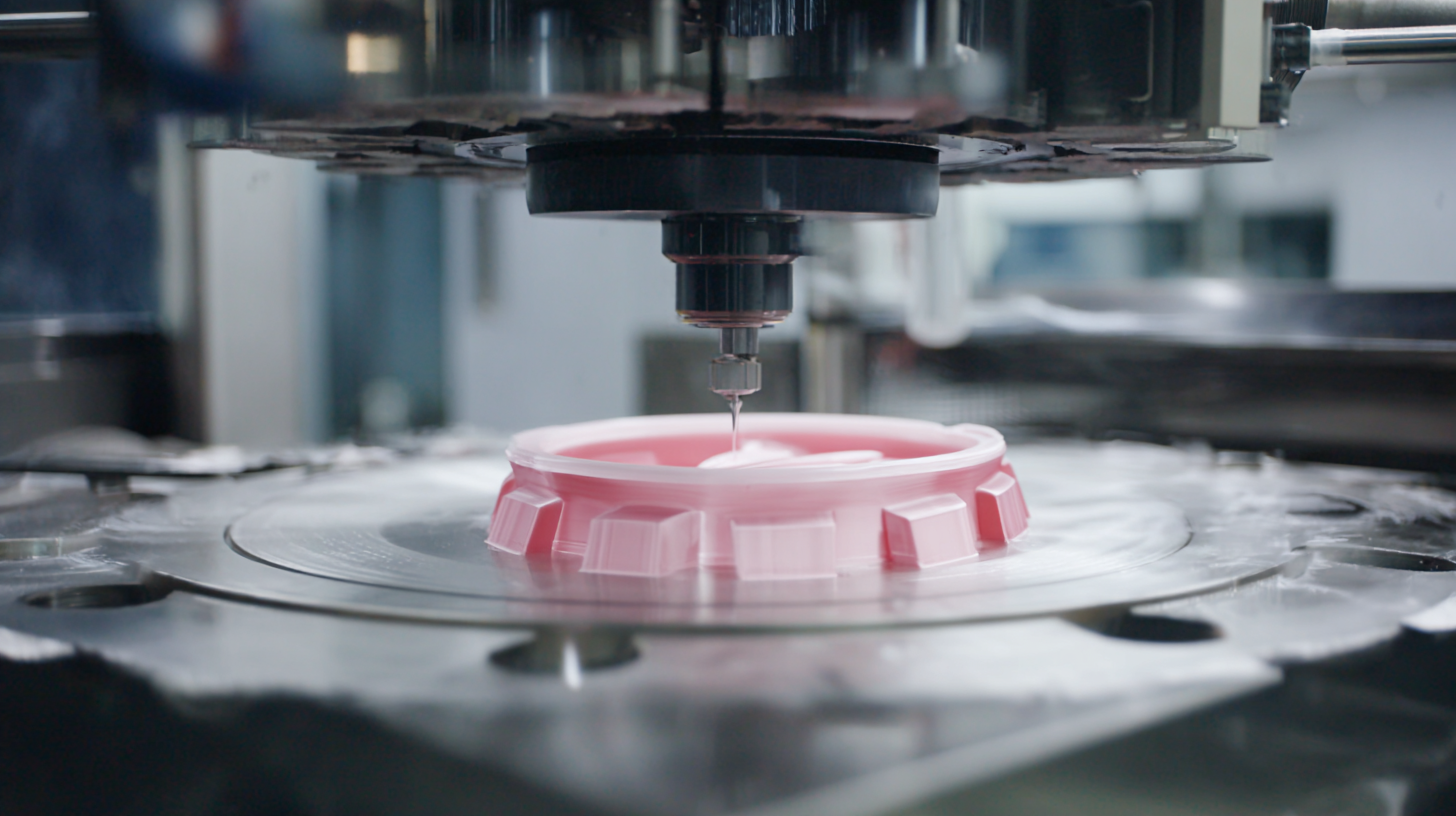

At the forefront of this shift is thermoforming, a process that allows for the efficient production of lightweight, recyclable packaging solutions. By utilizing thermoformed materials, companies can reduce waste, lower energy consumption, and enhance product protection. For instance, a study by the Packaging Association revealed that thermoformed packaging can cut material usage by up to 30% compared to traditional methods. As we explore the future of packaging, it is clear that thermoforming is playing a pivotal role in driving the adoption of sustainable practices across the industry, catering to the growing demand for eco-friendly solutions.

The Evolution of Thermoforming Technology in Packaging

The evolution of thermoforming technology in packaging is significantly shaping the future of sustainable solutions. Thermoforming, a process that involves heating plastic sheets to form a variety of shapes, has made substantial advancements over the past decade. According to a report by Smithers Pira, the global thermoforming market is expected to reach $12.45 billion by 2024, with a compound annual growth rate (CAGR) of 5.7%. This growth is largely driven by the demand for lightweight and recyclable packaging options, as consumers and manufacturers alike seek to reduce their environmental impact.

An emerging trend within thermoforming is the increasing use of biodegradable and recycled materials. According to a study by Grand View Research, the biodegradable packaging market is projected to expand at a CAGR of 14.8% from 2021 to 2028, indicating a strong shift toward more sustainable packaging solutions. Thermoformed products, such as trays and clamshells, are being designed to utilize these eco-friendly materials effectively. By embracing innovations in thermoforming technology, companies can not only enhance product protection and shelf-life but also respond to the growing demand for sustainability in packaging, thereby setting themselves apart in the competitive market landscape.

Sustainable Materials: A Shift Towards Eco-Friendly Solutions

The shift towards sustainable materials is gaining momentum across various industries, driven by increasing consumer demand for eco-friendly solutions. Businesses are now innovating packaging by adopting biodegradable polymers, glass, and plant-based alternatives. These materials not only reduce environmental impact but also cater to a growing market that values sustainability. The trend is particularly evident in sectors such as food packaging, where the global eco-friendly market is projected to double by 2032 as consumers seek recyclable and biodegradable options.

The shift towards sustainable materials is gaining momentum across various industries, driven by increasing consumer demand for eco-friendly solutions. Businesses are now innovating packaging by adopting biodegradable polymers, glass, and plant-based alternatives. These materials not only reduce environmental impact but also cater to a growing market that values sustainability. The trend is particularly evident in sectors such as food packaging, where the global eco-friendly market is projected to double by 2032 as consumers seek recyclable and biodegradable options.

In regions like India and Vietnam, the packaging sector is embracing this green growth in response to environmental pressures and market demands. Companies are rethinking their supply chains, focusing on zero waste packaging practices that prioritize recycling and reusing materials. This evolution is not just a trend but a necessary transformation towards a sustainable future, reflecting an industry-wide commitment to reducing pollution and energy consumption. As brands continue to explore innovative packaging designs, the marriage of functionality and sustainability is set to revolutionize how products are packaged and perceived.

Innovative Applications of Thermoformed Packaging in Various Industries

Thermoformed packaging is becoming increasingly important across various industries due to its innovative applications and the push for sustainable solutions. The market is witnessing a significant shift as brands seek eco-friendly alternatives, with pulp molding machines gaining prominence. As paper products are embraced as sustainable packaging materials, the pulp molding machine market is experiencing substantial growth. The versatility of thermoformed packaging allows it to meet diverse requirements in sectors such as food, medical, and consumer goods, providing efficient and environmentally friendly options.

In the medical field, sterile thermoformed packaging is revolutionizing how medical devices and supplies are presented and protected. This method not only ensures product integrity but also minimizes waste, aligning with the growing demand for sustainable practices. With a rising awareness of environmental issues, the adoption of thermoformed solutions that prioritize recyclability and reduced carbon footprints is becoming a priority for manufacturers. As industries continue to explore the innovative applications of thermoformed packaging, they will play a pivotal role in advancing sustainability and meeting consumer expectations for eco-conscious products.

Consumer Awareness and Demand for Sustainable Packaging Solutions

As consumer awareness surrounding environmental issues continues to grow, so does the demand for sustainable packaging solutions. Modern shoppers are increasingly making purchasing decisions based on a product's environmental impact, pushing companies to prioritize eco-friendly practices. This shift in consumer behavior has sparked a movement towards innovative packaging methods that reduce waste and promote sustainability.

Thermoforming, a process where plastic sheets are heated and molded into desired shapes, offers a compelling solution to meet this demand. It allows for the creation of lightweight packaging that not only conserves materials but also optimizes transportation efficiency. Furthermore, advancements in thermoplastics and bioplastics have made it possible to produce recyclable or even compostable materials that align with the values of environmentally-conscious consumers. As brands adapt to this new landscape, thermoforming stands out as a key player in the journey toward sustainable packaging, ensuring that businesses can meet consumer expectations while minimizing their ecological footprint.

Future Trends in Thermoforming and Sustainable Packaging Practices

The future of thermoforming technology holds significant promise in advancing sustainable packaging practices. As environmental concerns intensify, manufacturers are increasingly turning to thermoformed materials that are not only versatile but also eco-friendly. The technique allows for the production of lightweight, durable packaging solutions that reduce material usage and minimize waste. Innovations in bioplastics and recycled materials are paving the way for thermoformed products that maintain high performance while reducing their carbon footprint.

Emerging trends in the thermoforming industry are further driving the sustainability agenda. Companies are adopting closed-loop systems, where materials are reused and recycled, significantly lowering the demand for virgin resources. Additionally, advancements in digital printing technologies offer customized, on-demand packaging solutions that limit excess production. The integration of smart packaging elements is also gaining traction, as brands seek to enhance consumer experience while promoting eco-friendly practices. Through these evolving methods, thermoforming is not only reshaping the landscape of packaging but also fostering a more sustainable future.

Future Trends in Thermoforming and Sustainable Packaging Practices

Related Posts

-

Revolutionizing Consumer Electronics with Best Vacuum Forming Solutions for Common Manufacturing Challenges

-

Ultimate Guide to Choosing the Best Totes with Lids for Your Storage Needs

-

Choosing the Right Manufacturer for High Quality Best Stacking Bins

-

Unmatched Quality: China's Premier Large Plastic Bins Set Global Standards in Durability and Design

-

Innovative Storage Solutions Exploring Alternatives to Plastic Bins with Lids

-

Understanding the Advantages of Vacuum Forming Machines in Modern Manufacturing Processes