585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

The Future of Best Vacuum Forming Technologies in 2025 Your Ultimate Guide to Innovations

As we approach 2025, the landscape of vacuum forming technologies is set to undergo significant transformations that promise to enhance efficiency, sustainability, and versatility across various industries. This ultimate guide aims to illuminate the emerging trends and innovations within the realm of vacuum forming, showcasing how advancements such as advanced materials, automation, and smart manufacturing techniques are shaping the future. By exploring the anticipated developments, this article will provide valuable insights into the ways businesses can leverage these technologies to meet evolving consumer demands and environmental standards.

Whether you are a manufacturer, designer, or simply interested in the technological advancements of vacuum forming, this guide will equip you with the knowledge to navigate the exciting changes on the horizon.

Emerging Trends in Vacuum Forming Technologies for 2025

As we look ahead to 2025, the vacuum forming industry is poised for exciting advancements that promise to enhance the efficiency and versatility of this essential manufacturing process. One of the emerging trends is the integration of smart technology into vacuum forming machinery. Manufacturers are increasingly adopting IoT-enabled devices that provide real-time monitoring and data analysis. This shift not only improves production efficiency but also allows for predictive maintenance, minimizing downtime and optimizing resource usage.

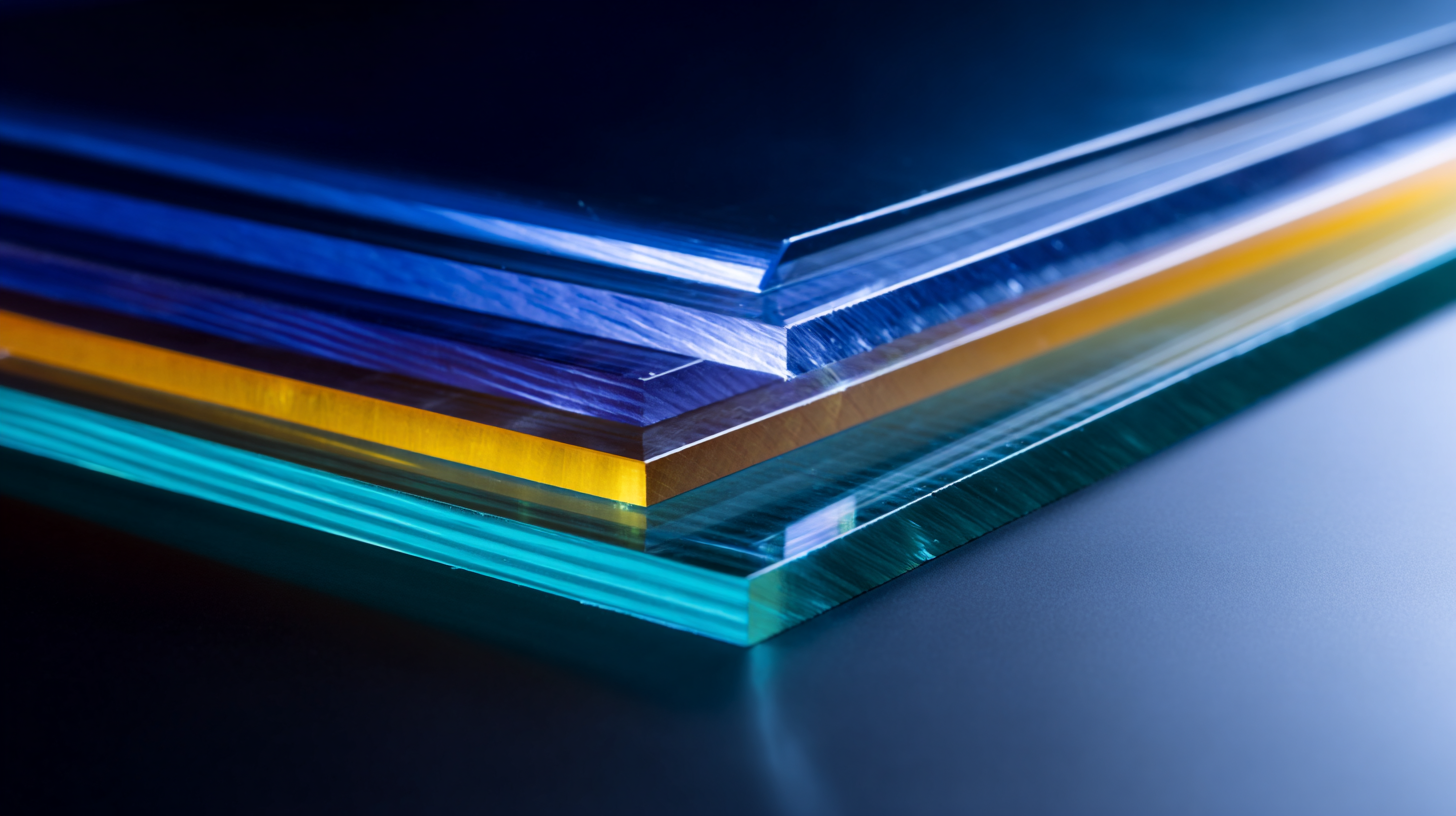

Another critical trend is the rise of sustainable materials in vacuum forming applications. With a growing emphasis on environmental responsibility, manufacturers are innovating with biodegradable plastics and recycled materials. This not only meets the consumer demand for eco-friendly products but also aligns with broader industry regulations aimed at reducing environmental impact. As these technologies develop, the market will likely see an increase in the use of advanced composite materials that offer enhanced strength and durability while still being lightweight. These trends signal a transformative period for vacuum forming technologies, paving the way for more efficient, sustainable, and consumer-oriented solutions by 2025.

Key Innovations Transforming the Vacuum Forming Industry

As we look towards 2025, vacuum forming technologies are undergoing significant innovations that promise to reshape the industry. One of the most notable advancements is the integration of automation and robotics in the production process. These technologies not only enhance efficiency but also improve precision in forming complex shapes, reducing waste and lowering production costs.

Tip: When considering vacuum forming for your projects, invest in systems that offer compatibility with automated machinery. This will not only speed up your production line but also allow for greater scalability as your business grows.

Additionally, the rise of sustainable materials is transforming the vacuum forming landscape. Manufacturers are increasingly leaning towards biodegradable and recyclable thermoplastics, driven by both regulatory changes and consumer demand for eco-friendly products. This shift not only helps in reducing environmental impact but also offers companies a competitive edge in the market.

Tip: Stay ahead by researching sustainable material options available for vacuum forming. Not only will this align with current trends, but it can also enhance your brand image by showcasing your commitment to sustainability.

The Future of Best Vacuum Forming Technologies in 2025

| Innovation | Description | Impact on Industry | Expected Adoption Year |

|---|---|---|---|

| 3D Printing Integration | Combining vacuum forming with 3D printing for custom molds. | Increased customization and reduced production time. | 2025 |

| Smart Vacuum Forming Machines | Machines equipped with IoT for real-time monitoring and adjustments. | Enhanced efficiency and reduced waste. | 2025 |

| Sustainable Materials | Use of biodegradable and recyclable materials in vacuum forming. | Lower environmental impact and improved product lifecycle. | 2025 |

| Automation and Robotics | Increased use of robotics for handling and finishing processes. | Higher productivity and reduced labor costs. | 2025 |

| Advanced Thermal Controls | Enhanced temperature management for better material performance. | Improved product quality and consistency. | 2025 |

Sustainability Practices in Vacuum Forming: A 2025 Overview

As the vacuum forming industry continues to evolve, sustainability practices are becoming central to competitive advantage, particularly as we look toward 2025. A recent report from the Plastics Industry Association indicates that 65% of manufacturers are now implementing eco-friendly materials in their production processes. This shift is not just a trend but a necessity driven by increasing regulatory pressures and consumer demand for sustainable packaging solutions.

Innovative materials such as bioplastics and recycled PET are gaining traction, allowing companies to maintain high-quality standards while reducing their ecological footprint.

Innovative materials such as bioplastics and recycled PET are gaining traction, allowing companies to maintain high-quality standards while reducing their ecological footprint.

In addition, advancements in technology are making it easier for manufacturers to adopt sustainable practices. For instance, the introduction of energy-efficient machines that utilize less power during the vacuum forming process has been reported to decrease energy consumption by up to 30%, according to a survey by the Society of Plastics Engineers. Furthermore, by optimizing the design for recyclability, companies can significantly enhance the lifecycle of their products. As vacuum forming continues to embrace these sustainable innovations, the industry is poised to not only meet but exceed environmental standards by 2025, fostering a greener future for all stakeholders involved.

How Chinese Factories are Leading Global Vacuum Forming Solutions

As we look toward 2025, the vacuum forming industry is witnessing a fascinating transformation, with Chinese factories at the forefront of innovation and production. These manufacturers are leveraging advanced technologies and streamlined processes to offer solutions that are not only cost-effective but also environmentally friendly. With a focus on automation and precision engineering, Chinese factories are capable of delivering high-quality vacuum-formed products that meet the growing demands of various industries, from packaging to automotive.

One of the key factors driving this leadership is China's investment in research and development. By integrating cutting-edge materials and enhancing production techniques, these factories are setting new standards for efficiency and sustainability. Moreover, the ability to scale quickly in response to market needs allows Chinese manufacturers to remain competitive on a global scale. As companies worldwide seek reliable partners in vacuum forming, China positions itself as a hub for innovation and quality, shaping the future of the industry as we approach 2025.

Future Challenges and Opportunities in Vacuum Forming Technologies

The vacuum forming industry is poised for significant transformations by 2025, driven by emerging technologies and shifting market demands. The global plastic vacuum forming market, valued at approximately USD 4.79 billion in 2023, is forecasted to grow at a compound annual growth rate (CAGR) of 6.15% between 2024 and 2030. This growth is propelled by innovations in materials and automation techniques, which are revolutionizing production capabilities and efficiency.

However, the transition is not without challenges. Issues related to sustainability and environmental impact are increasingly in focus, mirroring trends seen in other sectors such as battery recycling and hydrogen energy systems. As manufacturers adopt new technologies, they will need to navigate regulatory landscapes, optimize resource use, and address the environmental footprint of their processes.

Moreover, the integration of smart manufacturing principles—leveraging interconnected machines and real-time data analytics—presents both opportunities and hurdles for the industry, necessitating a balanced approach to innovation and responsible production methods.