585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

Mastering Custom Foam Packaging: A Step-by-Step Guide to Optimize Protection and Efficiency

In today's competitive landscape, the importance of custom foam packaging has surged to the forefront of effective product protection and brand presentation. According to a recent report by Smithers Pira, the global packaging market is projected to reach $500 billion by 2024, with specialized protective packaging, including custom foam solutions, playing a critical role in this growth. Custom foam packaging not only enhances safety during transit but also minimizes waste, addressing both economic and environmental concerns. As manufacturers and retailers alike seek to optimize their packaging strategies, mastering custom foam packaging can lead to improved efficiency, cost savings, and a significant reduction in product damage rates, thereby enhancing customer satisfaction and retaining brand integrity. With these factors in mind, this guide aims to provide a comprehensive overview of how to effectively design, implement, and benefit from custom foam packaging solutions in your operations.

Understanding the Importance of Custom Foam Packaging in Reducing Damage Rates by 20%

In today's competitive market, ensuring that products reach customers in pristine condition is critical. Custom foam packaging has emerged as a key solution, with industry studies indicating that effectively designed foam packaging can reduce damage rates by as much as 20%. According to a report by the Protective Packaging Association, adopting tailored foam solutions not only mitigates transit damages but also enhances perceived product value, making it a worthwhile investment for businesses aiming to bolster customer satisfaction.

Moreover, the National Institute of Standards and Technology highlights that 90% of shipping damage is attributable to inadequate packaging. Custom foam packaging addresses this by providing tailored support that conforms to product shapes, absorbing shocks and preventing movement during transportation. This highly engineered solution not only maximizes protection but also minimizes waste, exemplifying both efficiency and sustainability in packaging processes. As companies continue to seek innovative ways to reduce costs and improve delivery outcomes, custom foam packaging stands out as a vital component in the logistics chain.

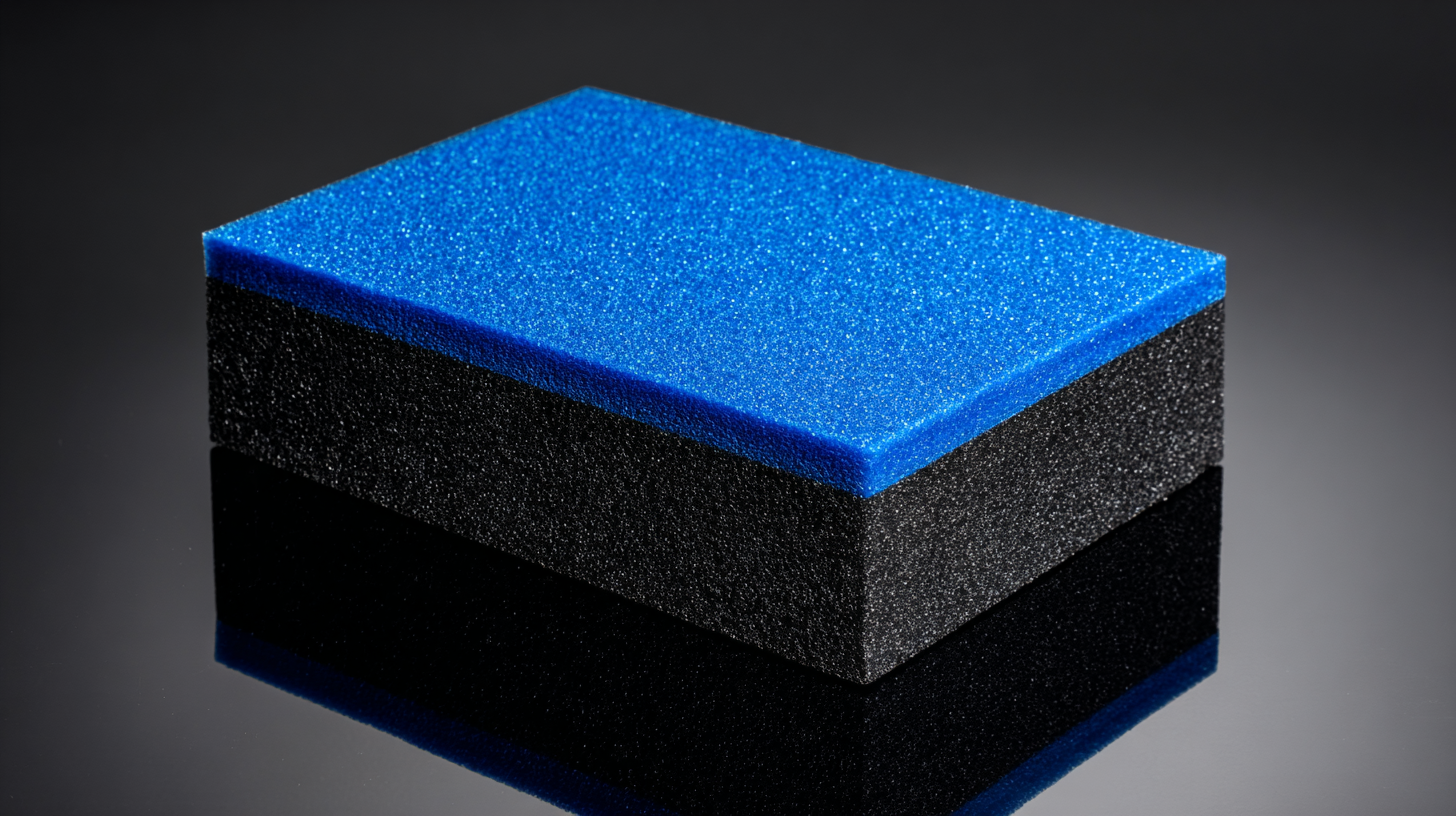

Key Materials in Foam Packaging: Exploring the Environmental Impact and Cost Efficiency

When it comes to foam packaging, the choice of materials significantly influences both environmental impact and cost efficiency. According to a report from Smithers Pira, the global market for protective packaging is anticipated to reach $50 billion by 2025, highlighting the increasing demand for effective solutions. Among the various materials available, polyethylene (PE) and polyurethane (PU) foam are the most commonly used. PE foam is not only lightweight and durable but also recyclable, which aids in reducing landfill waste. Conversely, PU foam, while offering superior cushioning properties, poses challenges due to its non-biodegradable nature.

In balancing environmental concerns and cost, manufacturers are increasingly turning to biodegradable foam options derived from plant-based sources. A study by Biofoam reveals that using such materials can reduce greenhouse gas emissions by up to 60% compared to traditional petroleum-based foams. Additionally, while the initial cost of these eco-friendly alternatives might be higher, the long-term savings from reduced waste disposal costs and improved brand reputation can offset this investment. Thus, businesses aiming to optimize their packaging solutions must carefully consider the life cycle impacts of their material choices to align their operations with sustainability goals while maintaining competitiveness in the market.

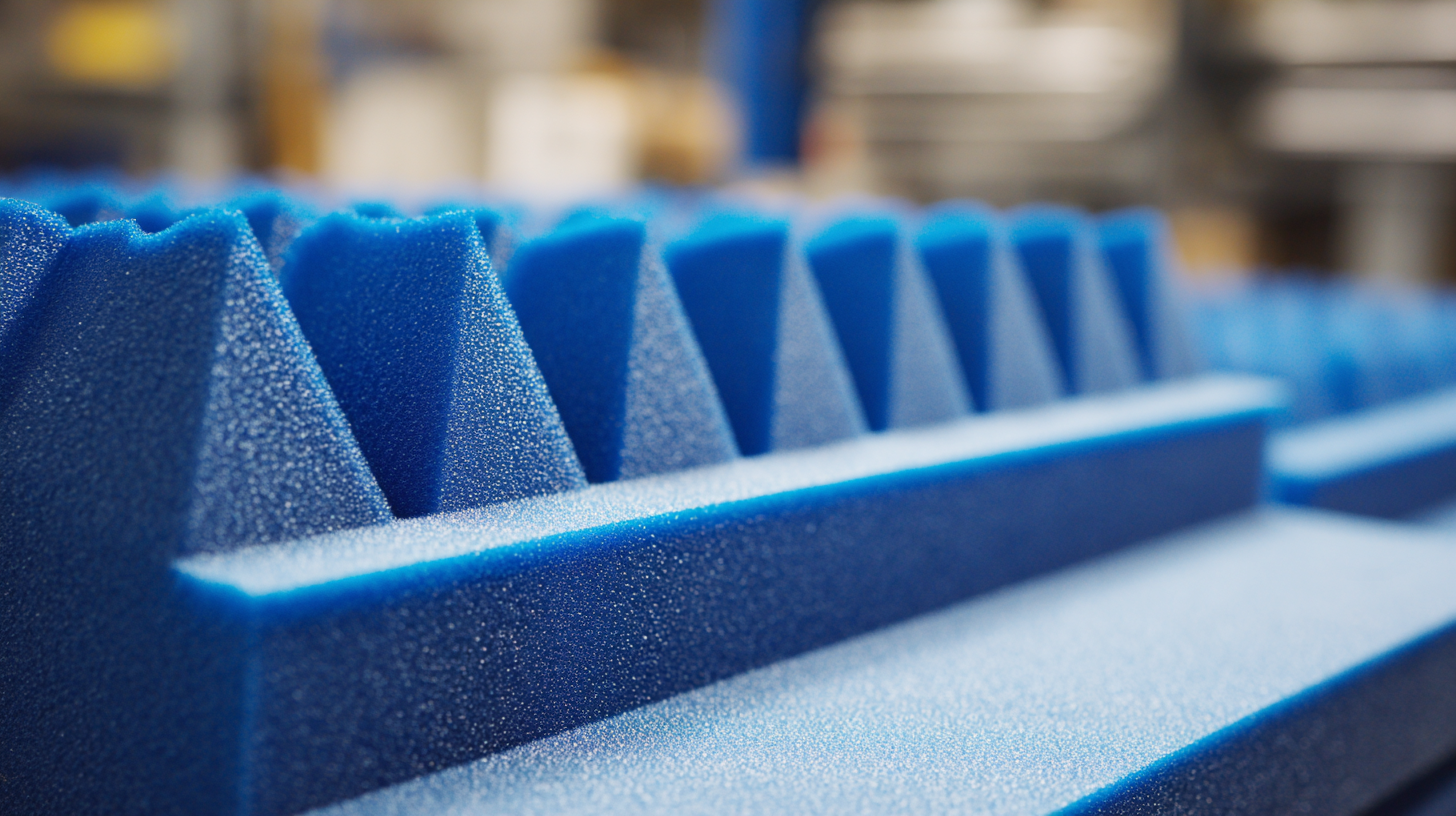

Designing for Protection: How Customization Can Lower Shipping Costs by Up to 15%

In today’s competitive shipping landscape, packaging plays a pivotal role in reducing costs and ensuring product safety. Custom foam packaging is an innovative solution that can significantly lower shipping expenses, with reports suggesting potential cost reductions of up to 15%. By designing packaging that fits the contours of the product, businesses can minimize movement within the box, thus reducing the risk of damage during transit. This targeted approach not only saves on shipping costs due to lighter, more efficient packaging but also enhances customer satisfaction by delivering items in perfect condition.

Moreover, the benefits of customization extend beyond just cost savings. Tailored foam inserts can optimize space usage, allowing companies to ship more products per freight load. This leads to fewer trips and reduced fuel consumption, further enhancing efficiency. The environmental impact is also noteworthy, as custom solutions often utilize fewer materials, contributing to sustainable practices. With thoughtful design and strategic placement, custom foam packaging not only protects valuable items but also significantly streamlines the shipping process, fostering a more cost-efficient and eco-friendly approach in logistics.

Optimizing Protection and Efficiency with Custom Foam Packaging

This chart illustrates the potential cost savings achieved by utilizing custom foam packaging for different shipping scenarios. The data reflects percentage reductions in shipping costs when using optimized foam protection compared to standard packaging solutions.

Step-by-Step Process: Implementing Foam Packaging Solutions in Your Supply Chain

Implementing foam packaging solutions in your supply chain can significantly enhance both product protection and operational efficiency. This process begins with an assessment of the specific needs of your products, including their fragility, weight, and dimensions. By understanding these factors, businesses can select the appropriate type of foam material—whether it's expanded polystyrene, polyurethane, or polyolefin—that best meets their requirements. This careful selection not only ensures that products remain intact during transit but also optimizes space utilization within packaging, leading to reduced shipping costs.

After material selection, the next step involves custom design. Utilizing computer-aided design (CAD) software can aid in creating tailored foam inserts that fit products snugly. This design phase is crucial as it minimizes movement within the packaging, further safeguarding the items during handling. Additionally, companies should incorporate eco-friendly practices, exploring biodegradable foam options that align with sustainability goals. By integrating these innovative solutions into the supply chain, businesses can not only improve their packing processes but also contribute positively to environmental conservation.

Evaluating ROI: How Custom Foam Packaging Increases Product Satisfaction by 30%

Custom foam packaging is rapidly gaining recognition for its ability to enhance product satisfaction significantly. According to recent evaluations, implementing custom foam solutions can yield up to a 30% increase in customer satisfaction. This statistic stems from several key factors that underscore the effectiveness of foam in protecting products during shipping and handling. The tailored fit of custom foam not only minimizes movement within the packaging but also provides a buffer against impacts, ensuring that products arrive in pristine condition.

Moreover, the aesthetics of custom foam can elevate the unboxing experience, making it memorable for consumers. A well-designed foam insert can reflect brand identity and quality, leaving a lasting impression that encourages repeat purchases. By prioritizing both protection and presentation, businesses can cultivate a relationship of trust with their customers. Investing in custom foam packaging is not merely a cost; it's a strategic decision that positively influences ROI by fostering loyalty and enhancing brand reputation, ultimately leading to increased sales.