585.204.6770

sale@sanblueplastics.com

Your Source for Trays!

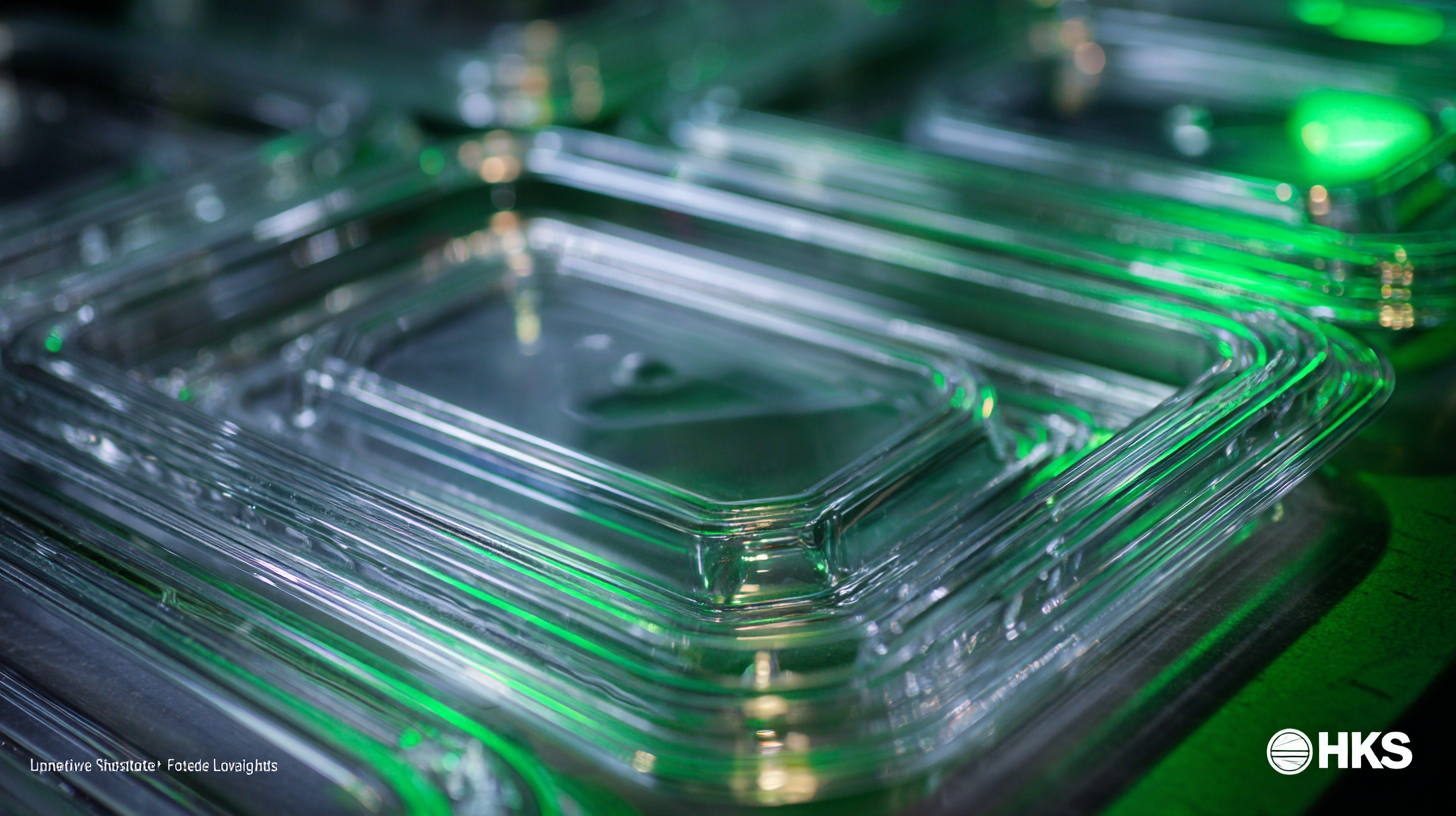

Maximizing Longevity and Reducing Maintenance Costs with Best Vacuum Forming Plastic Innovations

In the ever-evolving landscape of manufacturing, the adoption of vacuum forming plastic technologies has emerged as a pivotal strategy for maximizing longevity and minimizing maintenance costs. According to a recent report by Smithers Pira, the vacuum forming market is projected to reach $4.4 billion by 2024, driven by advancements in material quality and processing techniques. This growth underscores the industry's shift towards innovative solutions that enhance product durability while reducing lifecycle expenses. By utilizing best practices in vacuum forming plastic, manufacturers can not only improve product longevity—extending the average lifespan of plastic components by up to 30%—but also significantly lower maintenance needs and associated costs. As businesses aim for greater efficiency and sustainability, understanding and implementing these innovations becomes essential for staying competitive in a modern marketplace.

In the ever-evolving landscape of manufacturing, the adoption of vacuum forming plastic technologies has emerged as a pivotal strategy for maximizing longevity and minimizing maintenance costs. According to a recent report by Smithers Pira, the vacuum forming market is projected to reach $4.4 billion by 2024, driven by advancements in material quality and processing techniques. This growth underscores the industry's shift towards innovative solutions that enhance product durability while reducing lifecycle expenses. By utilizing best practices in vacuum forming plastic, manufacturers can not only improve product longevity—extending the average lifespan of plastic components by up to 30%—but also significantly lower maintenance needs and associated costs. As businesses aim for greater efficiency and sustainability, understanding and implementing these innovations becomes essential for staying competitive in a modern marketplace.

Innovative Vacuum Forming Techniques for Enhanced Durability

Innovative vacuum forming techniques are revolutionizing the production of durable plastic components across various industries, particularly in sectors like aerospace and automotive, where reliability and sustainability are paramount. By utilizing advanced materials and processes, manufacturers can enhance the longevity of vacuum-formed products while simultaneously reducing maintenance costs. The integration of additive manufacturing with vacuum forming has proven particularly effective, offering tailored solutions that meet specific design requirements and achieve better resource efficiency.

Innovative vacuum forming techniques are revolutionizing the production of durable plastic components across various industries, particularly in sectors like aerospace and automotive, where reliability and sustainability are paramount. By utilizing advanced materials and processes, manufacturers can enhance the longevity of vacuum-formed products while simultaneously reducing maintenance costs. The integration of additive manufacturing with vacuum forming has proven particularly effective, offering tailored solutions that meet specific design requirements and achieve better resource efficiency.

Moreover, the focus on eco-friendly materials is becoming increasingly critical as industries strive to meet sustainable development goals. The emergence of natural fiber composites offers a viable alternative to conventional materials, providing strength and biocompatibility. These innovations in vacuum forming not only enhance durability but also contribute to a more sustainable manufacturing landscape, highlighting a significant shift towards environmentally conscious production practices. As the plastic vacuum forming market continues to grow, it is essential for manufacturers to explore and adopt these innovative techniques to remain competitive and responsible stewards of the environment.

Cost-Effective Materials: The Future of Vacuum Forming Plastics

In the realm of vacuum forming plastics, the emphasis on cost-effective materials is transforming the industry landscape. Not only do these innovations lead to substantial cost savings, but they also promote sustainability by utilizing recyclable materials and reducing waste. By prioritizing materials that are both affordable and environmentally friendly, manufacturers can create high-quality products without inflating their expenses. This shift not only benefits companies but also positions them to meet the growing consumer demand for sustainable practices.

Furthermore, advancements in material technology have opened doors to emphasize durability alongside cost-effectiveness. Innovative plastics can now withstand harsh conditions and extended usage, minimizing the need for frequent replacements and reducing overall maintenance costs. As companies adopt these modern vacuum forming materials, they enhance product lifespan, ensuring customer satisfaction while also keeping operational costs low. This dual focus on affordability and longevity truly represents the future of vacuum forming plastics, illustrating that sustainable solutions can also be economically viable.

Sustainable Practices in Vacuum Forming for Longevity

In the pursuit of sustainability in manufacturing, vacuum forming stands out as a pivotal process that not only contributes to longevity but also plays a significant role in reducing environmental impact. By utilizing innovative and recyclable thermoplastics, companies can create durable products that withstand the test of time, thereby minimizing waste. These materials are engineered to be lightweight yet robust, ensuring that they do not compromise on quality while promoting eco-friendly practices.

The adoption of sustainable practices in vacuum forming is evident through the implementation of energy-efficient machinery and optimized production techniques. This not only lowers the carbon footprint of the manufacturing process but also cuts down on maintenance costs. By choosing advanced technologies that reduce energy consumption and waste, manufacturers can achieve superior product longevity and operational efficiency. As such, embracing these innovations not only benefits the environment but also enhances profitability, making sustainability a win-win for businesses and the planet.

Maximizing Longevity and Reducing Maintenance Costs with Best Vacuum Forming Plastic Innovations

Comparative Analysis: Traditional vs. Advanced Vacuum Forming Methods

In the comparative analysis of traditional versus advanced vacuum forming methods, recent studies have highlighted significant advancements in materials and processes that enhance performance and reduce costs. For instance, research on wood flour-high-density polyethylene composites illustrates how varying wood content can improve the thermoforming behavior of these materials, which is essential for producing lightweight yet durable products. This innovative approach not only maximizes longevity but also lowers maintenance costs associated with traditional plastic sheets that often suffer from rapid wear and inefficiency.

Furthermore, advances in vacuum forming techniques are being complemented by the integration of 3D printing, which presents a transformative opportunity for industries like orthotics. Traditional methods, such as plaster molding for ankle-foot orthoses, are gradually being replaced by automated processes that ensure precision and adaptability. A 2023 study emphasizes the thermo-mechanical properties of 3D printed materials, suggesting that they offer comparable performance to conventional vacuum-formed products, while significantly reducing the time and costs involved in manufacturing. This shift not only aims to streamline production but also promises a new era of customization and efficiency in plastic forming technology.

Maximizing Longevity and Reducing Maintenance Costs with Best Vacuum Forming Plastic Innovations

| Method | Material Used | Durability (Years) | Maintenance Cost (Annual) | Energy Consumption (kWh) | Production Speed (Units/hour) |

|---|---|---|---|---|---|

| Traditional Vacuum Forming | PVC | 5 | $500 | 15 | 10 |

| Advanced Vacuum Forming | ABS | 10 | $300 | 10 | 15 |

| Hybrid Vacuum Forming | Polycarbonate | 15 | $400 | 12 | 12 |

| Eco-Friendly Vacuum Forming | Biodegradable Plastics | 8 | $250 | 8 | 18 |

Real-World Applications: Success Stories of Efficient Vacuum Forming Solutions

Vacuum forming has proven to be a transformative technology in various industries, particularly in packaging, automotive, and consumer products. Companies integrating innovative vacuum forming solutions are experiencing remarkable efficiency gains. For instance, a recent study by the Plastics Industry Association found that manufacturers can reduce production costs by up to 30% when adopting advanced materials and processes in vacuum forming. Successful applications in sectors like food packaging highlight how these solutions not only enhance product durability but also maximize shelf life, ultimately leading to better customer satisfaction.

Tips: When considering vacuum forming solutions, always assess the environmental impact of the materials used. Opting for recyclable plastics can lead to sustainable production practices. Additionally, investing in modern machinery can enhance precision and reduce waste, ensuring that the benefits of vacuum forming truly resonate across your operations.